Electron Beam Cladding

Electron beam cladding technology enables precise dosing of additive material and adjustment of layer thickness. This supports the exact control of the material formation and hardness.

Cladding with electron beam is a thermal process.

It adds metal wire directly into a molten pool. The vacuum conditions refine the resulting surface structure for improved hardness and corrosion resistance of the substrate.

Die Kombination aus hohem T/D-Verhältnis und schneller Bohrgeschwindigkeit hebt EB Bohren von allen anderen mechanischen, chemischen und auch anderen thermischen Technologien zur Herstellung kleiner Bohrungen ab.

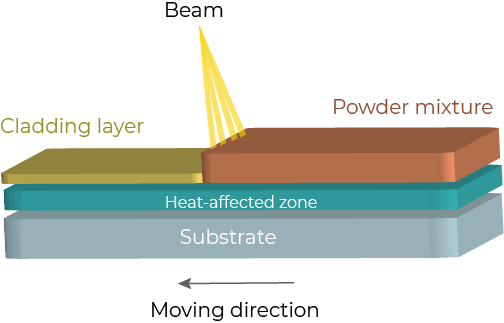

Electron Beam Cladding Principle

The dynamic deflection capabilities of the electron beam allow for a wider area of the workpiece to be treated.

In the focal spot, the electron beam melts the workpiece and the additive material. Due to the high frequency deflection of electron beam, a defined area of metal is molten.

For optimized chemical and metallurgical properties of the new layer, it is essential to precisely control and adjust beam power and diameter. Electron beam technology is ideally suited for this.

Electron Beam Cladding Features and Benefits

Electron beam cladding is beneficial for the resulting material properties and productivity.

- Controlled layer thickness:

The precise electron beam properties controls energy density and distribution and thus the cladding layer thickness with powder as additive material. - Defined material properties:

Due to the exact energy input and layer thickness, the hardness and corrosion resistance are controllable. - Refined surface and structure of cladding layer:

Vacuum conditions of electron beam cladding positively impacts surface and structure.

- Fully automated cladding:

A fully automated electron beam cladding precisely repeats and fully traces the parameters per layer and thus securely controls and documents the complete process per workpiece.

Electron Beam Cladding Additional Information

Cladding could be perceived as an additive manufacturing method. However, the focus is to modify the material properties of a given workpiece shape by adding a single or few material layers.

Electron Beam - Systems & Options

Versatile range of electron beam machining solutions supported by our scope of services