DAM Diffusion Bonding

DAM Diffusion Bonding Additive Manufacturing – System for bonding of different materials

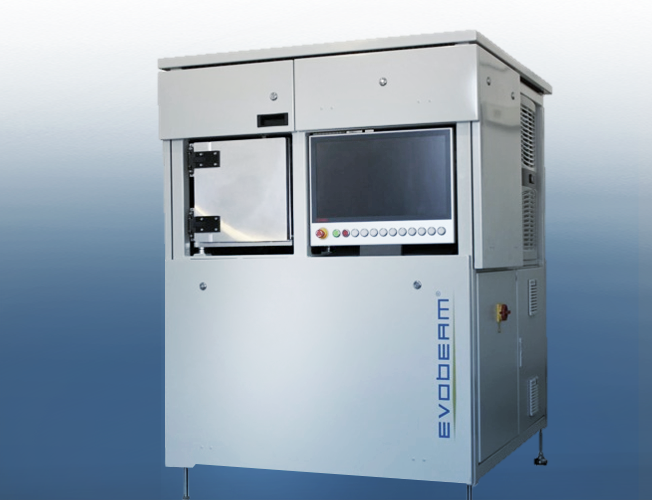

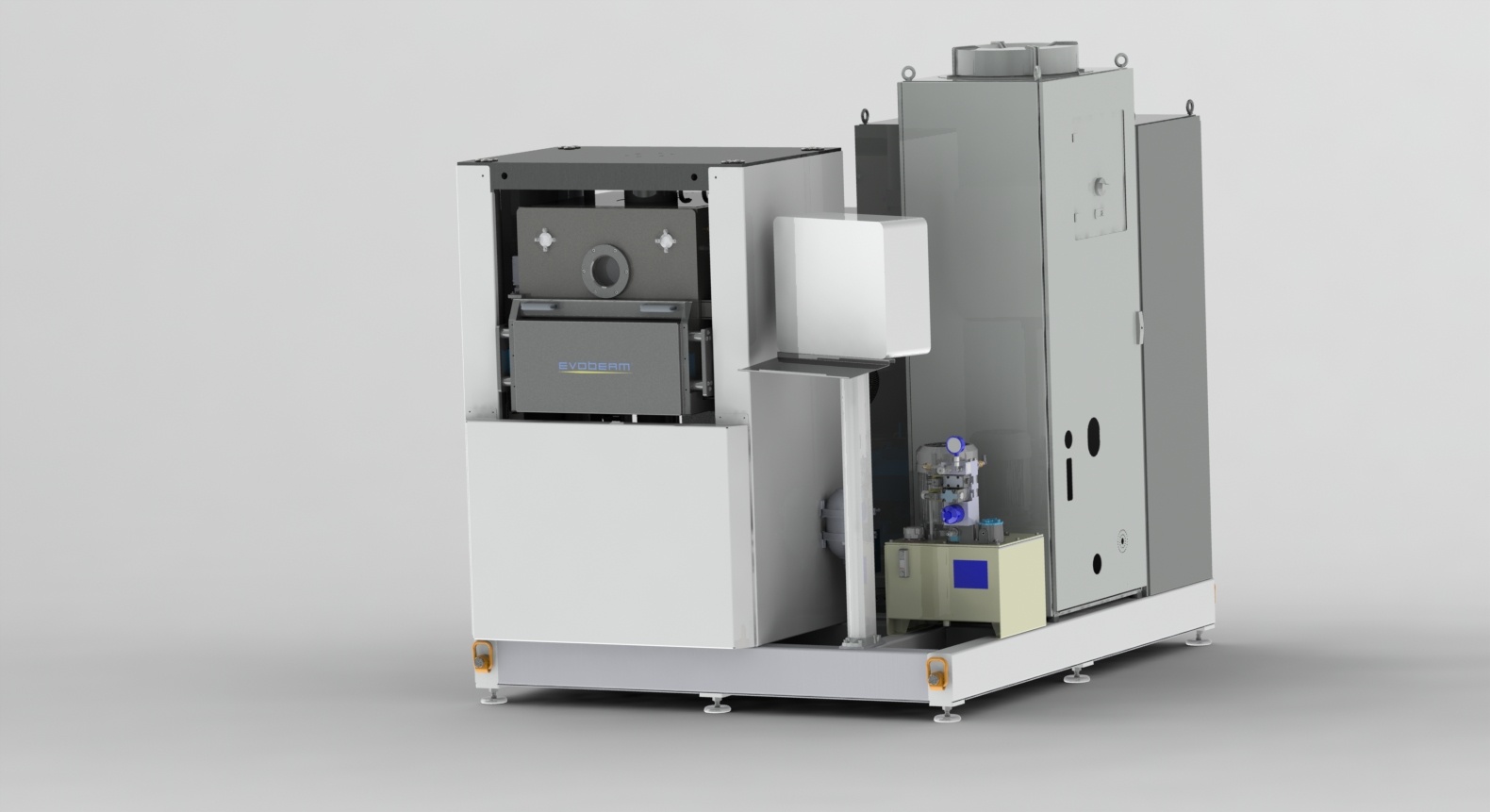

Evobeam DAM Diffusion Bonding Features

- Compact design with water cooled vacuum work chamber available in different sizes

- For TiAl, refractory metals and super-alloys

- Dry vacuum up to ≤ 1 x 10-4 mbar

- Resistive heating ≤ 1400°C

- Controllable column press force

- Thermal camera

- Top loading drawer

Diffusion Bonding – Benefits

- Enables complex internal hollow structurs such as cooling channels in molds and dyes

- Layerwise bonding of conventionally unweldable metals or metal ceramic sandwiches

- Minimized cool down time due to water cooled chamber walls and additional ventilator significantly reduces overall processing time

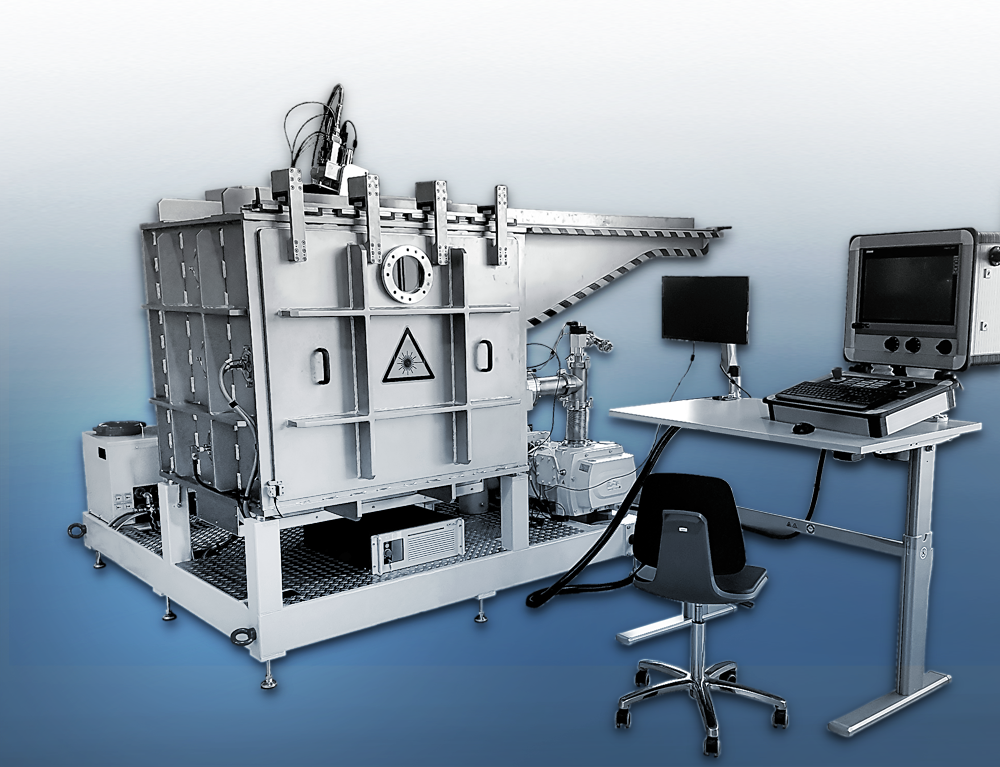

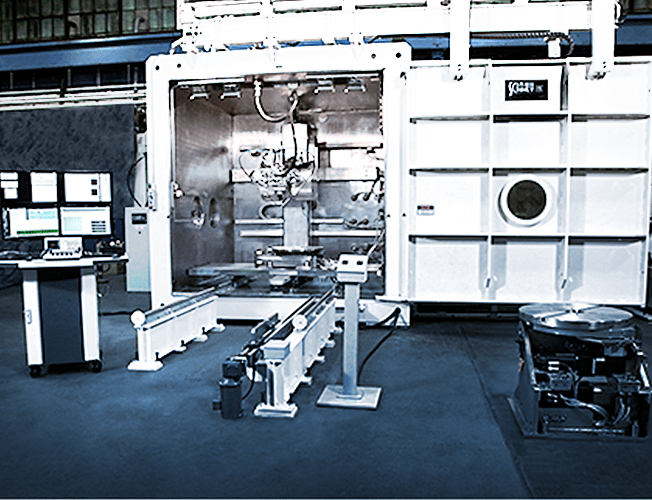

Additive Manufacturing Systems

Alternative solutions for your requirements