Laser in Vacuum Cladding

Laser in vacuum cladding technology enables precise control of layer properties with low heat input into the base material.

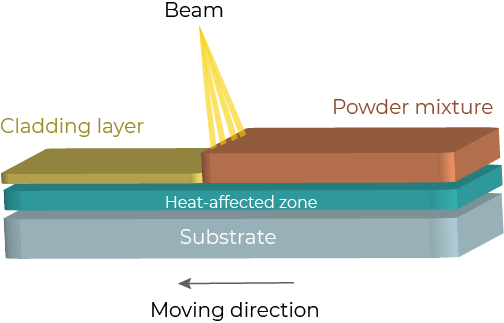

Cladding with laser beam is a thermal process that adds material directly into a pool of molten metal. This additional material can be applied at powder or wire.

Due to the vacuum conditions, the resulting surface structure is refined. Laser beam cladding in non-vacuum conditions is possible as well.

Cladding is applied for increasing hardness and corrosion resistance of the base or substrate material.

Laser Beam Cladding Principle

Usually, a wider area of the workpiece shall be treated. So, the dynamic deflection capabilities of the laser beam come into place.

In the focal spot, the laser beam heats up the workpiece and the additive material above its melting point. Due to the high frequency deflection of laser beam, an area with molten liquid metal is formed.

For optimized chemical and metallurgical properties of the new layer, it is essential to precisely control and adjust the parameters, beam power and beam diameter amongst others.

Laser beam cladding has several features, which are beneficial for the resulting material properties and productivity. Especially, as laser beam cladding is possible in non-vacuum conditions, a robotized application for larger workpieces can be applied.

- Controlled layer thickness:

The precise control of the laser beam properties with respect to energy density and location allows to control the cladding layer thickness when used with powder as additive material.

- Defined material properties:

Due to the exact control of energy deposit and layer thickness, it is possible to define the resulting material properties with respect to hardness and corrosion resistance.

- Refined surface and structure of cladding layer:

Vacuum conditions of laser beam cladding have positive impact on resulting surface and structure.

- Fully automated cladding:

Fully automated laser beam cladding machines enable extremely precise repeatability and full traceability of relevant cladding parameters during the cladding process itself. This applies per cladding layer and per workpiece. So, the cladding process of each item can be securely controlled and documented.

Laser Beam Cladding Additional Information

Cladding could be perceived as part of the additive manufacturing technologies. As the main focus of cladding is to modify the material properties instead of building up complete new shapes and workpieces, we allocate this technology to laser beam machining for the time being.

EVOBEAM supplies the optimum solution for the specific cladding application in vacuum for high production rates: cost-effective, fast, and versatile.

Laser in Vacuum - Systems & Options

Versatile range of laser in vacuum machining solutions supported by our scope of services